Scroll saw basics have gotten complicated with all the blade options and specialty techniques flying around. As someone who started scroll sawing as a teenager cutting out wooden ornaments in my dad’s garage, I learned everything there is to know about blade selection and pattern cutting over the years. Today, I will share it all with you.

What a Scroll Saw Actually Does Best

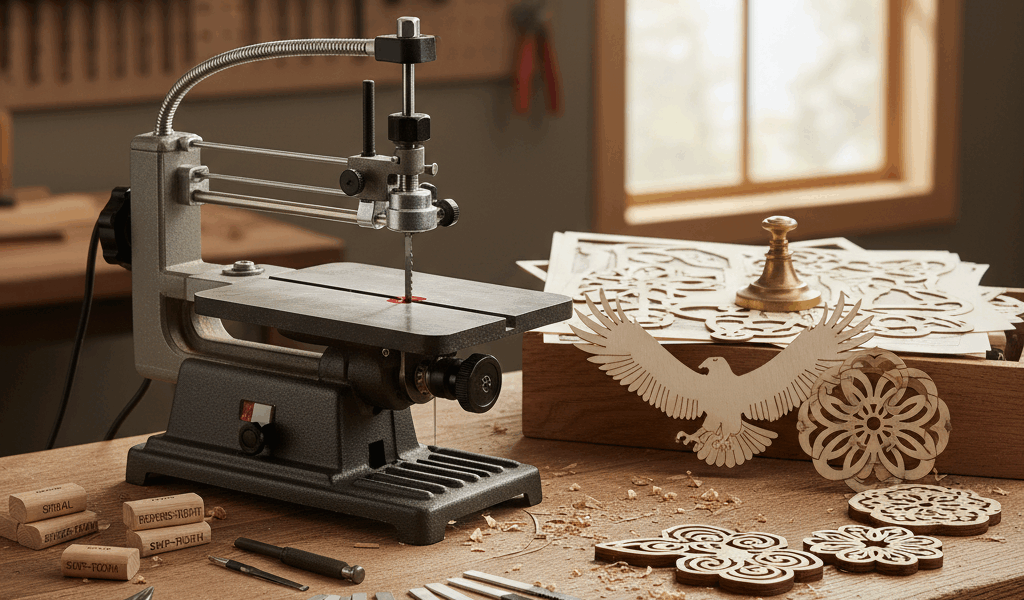

A scroll saw is not just a small bandsaw. It does something no other saw in your shop can do — it cuts intricate interior shapes. You drill a hole, thread the blade through it, and cut from the inside out. Try that on a bandsaw. That’s what makes the scroll saw endearing to us woodworkers who love detailed work — it lets you cut things that are simply impossible with other tools.

The thin blades turn incredibly tight curves. We are talking quarter-inch radius turns on some of the finer blades. Fretwork, intarsia, puzzles, jewelry boxes with cutout patterns — this is scroll saw territory. Delicate work is the specialty, and once you get comfortable with the machine, you will find yourself designing projects just because you can cut them.

Blade Selection — Getting This Right Matters Most

Probably should have led with this section, honestly. The blade makes or breaks your scroll saw experience, and most beginners never get past the generic blades that come in the box.

Skip tooth blades are your workhorse for most wood cutting. The missing teeth create space for sawdust to clear, which means less burning and smoother cuts. I use skip tooth blades for ninety percent of my cutting. Number five is a good all-around size for three-quarter-inch stock.

Spiral blades cut in all directions, which means you can change direction without rotating the workpiece. Sounds amazing, right? It is, for certain applications. But the cut is wider and rougher than a standard blade. I use spirals for rough work and inside cuts where I need maneuverability. For anything that shows, I go back to standard blades.

Finer teeth give you a smoother cut for delicate work. A number two or number three blade on thin hardwood produces a cut so clean it barely needs sanding. Coarser teeth — number seven, number nine — cut faster through thick stock but leave a rougher edge. Match the blade to the job. I keep a whole drawer organized by blade number so I can swap quickly.

Tensioning Your Blade Properly

Blade tension is the single most overlooked adjustment on a scroll saw. Proper tension prevents the blade from wandering left or right during a cut. Too loose and the blade deflects, giving you angled cuts that are wider at the bottom than the top. Too tight and you will snap blades constantly, which gets expensive and frustrating fast.

Here is the test I use. Pluck the blade like a guitar string. It should give a clear, high-pitched ping. A dull thud means it is too loose. If it barely moves when you pluck it, back off the tension a quarter turn. Every blade type takes slightly different tension, so check each time you swap.

Technique Tips From Years of Cutting

Feed slowly. The number one mistake I see beginners make is pushing too hard and too fast. Let the blade do the cutting. Your job is to steer. If you are forcing the wood into the blade, either your blade is dull or you are trying to cut faster than the blade can handle.

Turn the work, not the blade. This is counterintuitive at first, but you will get much smoother curves by rotating the workpiece around the blade rather than trying to steer the blade through the wood. I use both hands on the piece and make small rotational adjustments as I go.

Practice on scrap first. Every new pattern or blade type deserves a few test cuts before you commit to your good wood. I keep a stack of quarter-inch plywood scraps next to my scroll saw for exactly this purpose. Five minutes of practice saves you from costly mistakes on the real thing.