Finishing is where projects go from “I made this” to “I can’t believe I made this.” The right tools make the difference between a frustrating, blotchy mess and a smooth, professional result.

Sanders: Your First Investment

Random orbit sander: If you buy one power sander, make it this. The random pattern means no swirl marks, and 5-inch discs are cheap and everywhere. I’ve used the same DeWalt for years—nothing fancy, just reliable.

Quarter-sheet palm sander: Good for detail work and getting into corners where the random orbit won’t reach. These are cheap, light, and useful for final smoothing. They don’t remove material fast, which is actually a feature when you’re finishing.

What about belt sanders? Honestly, I rarely reach for mine. They’re aggressive and hard to control. Useful for flattening large surfaces or removing a lot of material, but not really finishing tools. Keep it for rough work.

Spraying vs. Brushing vs. Wiping

The tool you use to apply finish matters almost as much as the finish itself.

HVLP spray guns: For production work or when you need a glass-smooth finish. Learning curve is steep, cleanup is annoying, and you need ventilation and a spray booth. But the results are unmatched. I use mine for lacquer and conversion varnish on furniture pieces.

Good brushes: A quality natural bristle brush for oil-based finishes, synthetic for water-based. Don’t cheap out—a $15 brush lays down finish smoother than a $3 chip brush and doesn’t shed bristles into your wet finish. Clean them properly and they last years.

Wipe-on application: My go-to for most projects. Flood the finish on with a rag, wipe off the excess, let it dry, repeat. Works for oil finishes, wipe-on poly, and Danish oil. Hard to mess up, no brush marks, no overspray.

Between-Coat Prep

Sanding blocks: After the first coat raises the grain, you need to knock it back down. A flat sanding block with 320 grit does this quickly. Don’t use your palm—you’ll round edges and create uneven spots.

Steel wool: 0000 steel wool is great for scuffing between coats of oil finish. Leaves a smoother surface than sandpaper. Just make sure you get all the steel fibers off before applying the next coat—they rust.

Synthetic abrasive pads: Scotch-Brite style pads won’t leave steel particles behind. Good alternative to steel wool, especially for water-based finishes where rust contamination would be a disaster.

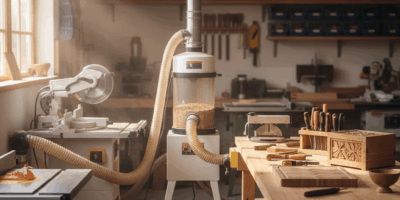

Dust Control

Dust in your finish is the enemy. A tack cloth picks up particles right before you apply finish. Work in a clean space, let airborne dust settle after sanding, and don’t wear fuzzy sweaters to the shop.

The Minimal Setup

You don’t need everything at once. A random orbit sander, some quality rags, a good brush, and a sanding block will handle 90% of finishing work. Add specialized tools as specific projects require them.