Dust collection strategies have gotten complicated with all the cyclone separators, air filtration units, and micro-dust concerns flying around. As someone who spent the first few years of my woodworking journey ignoring dust collection and paying for it with a persistent cough, I learned everything there is to know about keeping your shop air clean. Today, I will share it all with you.

Why This Is a Health Issue, Not Just a Cleanup Issue

Wood dust causes respiratory problems. Full stop. This is not fear-mongering — it is documented medical fact. Fine dust particles under ten microns are the real danger because they get past your nose and throat and lodge deep in your lungs. Some species like cedar, walnut, and cocobolo are especially irritating and can trigger allergic reactions. Long-term exposure to wood dust is linked to nasal cancer. Invest in dust collection or pay with your health. I chose the hard way first and regret it.

That’s what makes a good dust collection system endearing to us woodworkers who plan on doing this for decades — it keeps you healthy enough to keep making things.

Source Collection — Catch It Where It Starts

Probably should have led with this section, honestly. The most effective dust collection happens right at the tool where the dust is generated. Every major power tool in your shop should have a dust port connected to your collection system.

Hoods and ports come in different configurations for different machines. Table saws need collection below the blade and ideally an overarm guard with a dust port too. Planers and jointers generate huge volumes of chips and need high-airflow connections. Sanders produce the finest and most dangerous dust. Make sure every tool has an appropriately sized port that matches your ductwork.

Floor sweeps positioned at strategic spots catch the dust that settles before you can get it. I have one under my miter saw station and one under my workbench. A quick foot kick opens the blast gate and the floor sweep grabs everything within a couple feet.

If you run ductwork to multiple tools, blast gates are essential. Open the gate to the tool you are using and close the others. This concentrates all the suction power where you need it. Running all gates open means weak suction at every port.

Collector Types — Matching to Your Shop

Single-stage collectors pull everything — chips, dust, and shavings — through the impeller and into a bag or canister. They work fine for small shops with one or two machines running at a time. Simple, affordable, and better than nothing by a huge margin. I started with a single-stage Harbor Freight collector and it served me well for several years.

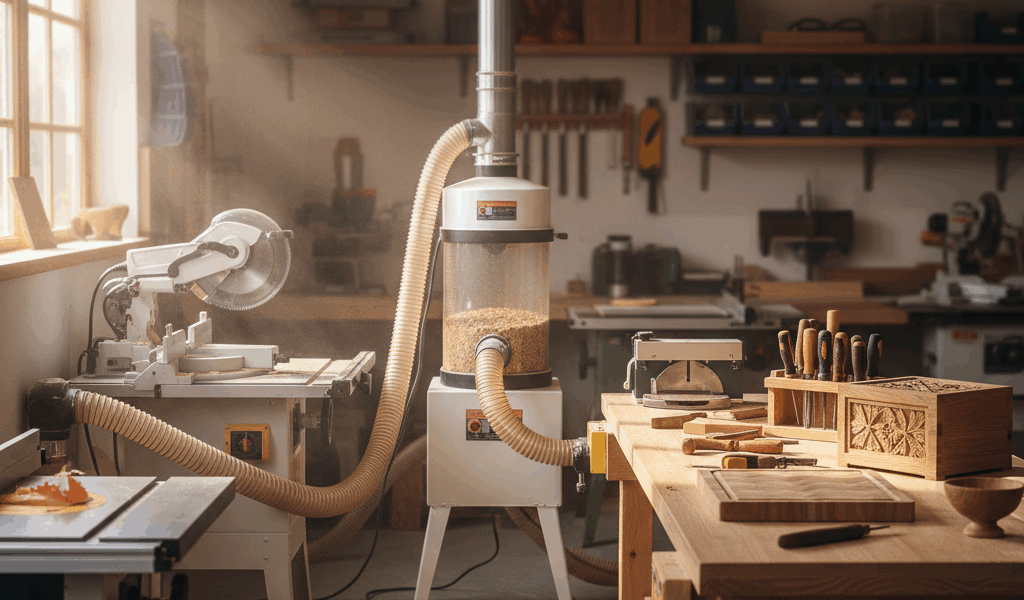

Two-stage collectors use a separator — usually a cyclone or a Thien baffle — to drop the heavy chips into a bin before the fine dust reaches the filter. This dramatically extends filter life and improves suction because the filter stays cleaner longer. If you can afford the upgrade, two-stage is the way to go.

Cyclone separators are the gold standard for workshop dust collection. They spin the incoming air so centrifugal force separates heavy material into a collection drum while fine dust passes to the filter. My shop runs a two-horsepower cyclone and it handles six-inch ductwork to every major machine. Worth every penny.

CFM ratings indicate airflow capacity. Your table saw needs roughly three hundred to four hundred CFM. A planer needs more. Check your tool requirements and size your collector accordingly. Undersized collection means dust escaping at the tool — which defeats the purpose.

Filtration — The Part Most People Skimp On

One-micron filtration is the minimum I recommend. Standard thirty-micron felt bags that come with cheap collectors are essentially useless for fine dust — they stop the chips but pass the dangerous particles right through and blow them back into your shop air. Upgrade to a pleated one-micron canister filter if your collector supports it.

HEPA filtration adds another level of protection for people who are sensitive or who work with exotic species known to cause respiratory issues. An ambient air filtration unit hung from the ceiling catches the dust that escapes your source collection and filters the room air continuously. I run mine for thirty minutes after I stop working to clear the remaining suspended particles.

Clean or replace filters on a regular schedule. A clogged filter reduces airflow and stops your system from working properly. I check my canister filter monthly and clean it with compressed air. Replace when cleaning no longer restores suction.