Table saw safety has gotten complicated with all the flesh-sensing technology debates and guard controversies flying around. As someone who has used a table saw nearly every day for over twenty years without a serious injury — and who has seen what happens when people get careless — I learned everything there is to know about staying safe around the most dangerous tool in the shop. Today, I will share it all with you.

Blade Guards — Use Them

I know, I know. A lot of woodworkers remove the blade guard and toss it in a corner on day one. I did it myself for years. But modern guards have come a long way from the clunky plastic shrouds that came on older saws. A good overhead guard with a dust collection port gives you visibility, protection, and chip extraction all at once.

Splitters and riving knives prevent kickback by keeping the wood from pinching closed on the back of the blade. This is the single most important safety device on your table saw. Even if you take the guard off for certain operations, leave the riving knife in place. Kickback happens in a fraction of a second and sends a board flying at you faster than you can react. A riving knife prevents it entirely.

Anti-kickback pawls add another layer of protection. They allow the wood to move forward but dig in and catch it if it starts to come backward. Not everyone uses them, but they are cheap insurance. That’s what makes proper table saw safety endearing to us woodworkers who want to keep all ten fingers — the protection is available if you just bother to use it.

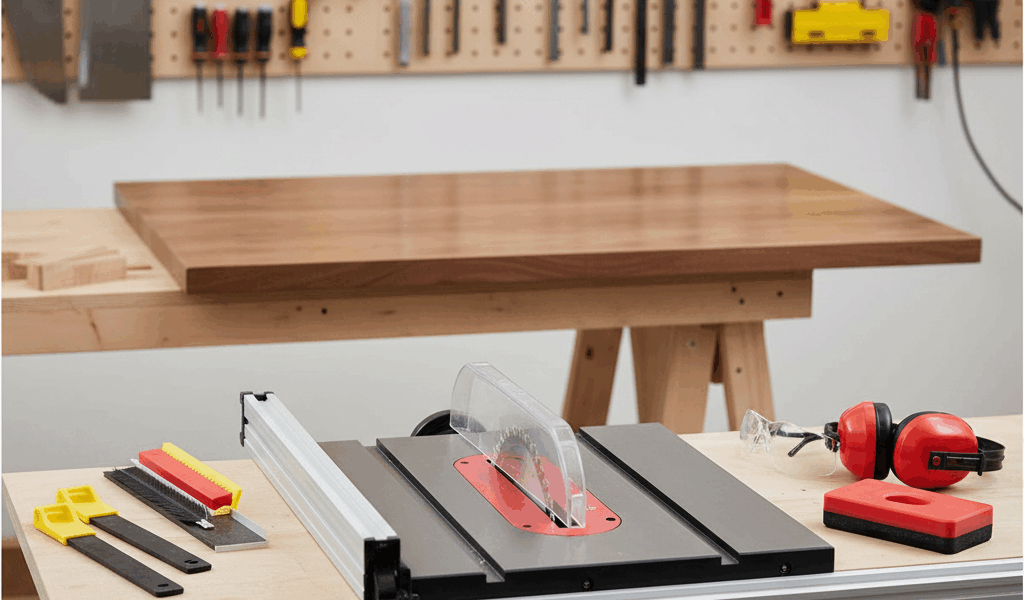

Push Sticks and Push Blocks

Probably should have led with this section, honestly. Your hands should never be within six inches of a spinning table saw blade. Period. Push sticks keep your hands at a safe distance while giving you control over the workpiece.

Different operations call for different push devices. A standard push stick with a notch at the end works for ripping boards. A push block with a wide base and a handle on top gives you more control over wide panels. A push shoe with a rubber sole grips the workpiece surface for thin stock that a push stick might tip. I keep all three types within arm’s reach of my table saw.

Make extras. Seriously. I make push sticks from scrap plywood by the half dozen. They live in a rack right next to the saw so there is never an excuse not to use one. If a push stick gets chewed up by the blade, toss it and grab another. They are free and they keep your fingers attached to your hands.

Preventing Kickback

Never stand directly behind the blade during a cut. Stand to the left side of the blade path if you are right-handed. If kickback happens, the board launches straight back from the blade. Being off to the side means it misses you. I have been kicked back at twice — both times early in my career when I was standing in the wrong spot. The board hit the shop wall hard enough to dent the drywall. That could have been my stomach.

Use a splitter or riving knife on every single through cut. No exceptions. Never cut a freehand piece between the fence and the blade — this traps the offcut and guarantees kickback. The offcut must always have room to fall away freely from the blade.

Support your outfeed adequately. A board that drops off the back of the table can pivot on the blade edge and kick back. An outfeed table, roller stand, or even a sawhorse positioned behind the saw prevents this. I built a dedicated outfeed table that doubles as an assembly surface, and it is one of the best shop improvements I have ever made.

Ongoing Maintenance for Safety

Blade alignment directly affects safety. A blade that is not parallel to the fence causes binding and increases kickback risk. Check your blade alignment when you first set up the saw and recheck it periodically. It takes five minutes with a dial indicator or a simple test cut.

A clean, sharp blade provides cleaner cuts with less force, which means less chance of the workpiece binding or the operator pushing too hard. Replace or sharpen blades when they start burning wood or requiring extra feed pressure.

Check fence parallelism regularly. A fence that toes in toward the blade at the back is a kickback machine. Most fence systems allow micro-adjustment — set it so the fence is dead parallel to the blade or slightly toed out at the back. Never toed in.

Inspect your throat plate for damage. A cracked or warped insert can let thin offcuts drop into the saw body and get launched out. Zero-clearance inserts are safer than standard inserts because the narrow kerf prevents small pieces from dropping through.